Introduction to types of welding defects

I- Weld Defects

- In manufacturing welded, usually divided into two main defects: Defect when preparing welding (pre- fitting joints) and defects occur during welding. Weld defects may occur on the outside (surface) either within the weld.

- There are 4 main types Weld defects often occur:

A. Defects visible to the eye (Visual inspection):

Shown in 5 main types of disabilities :

1. Cracks

2. Surface irregularities

3. Contour defects .

4. Root defects.

5. Surface porosity.

2. Surface irregularities

3. Contour defects .

4. Root defects.

5. Surface porosity.

B. Defects not be visually checked to use NDT methods (Non - destructive Testing)

Usually divided into 5 major types of disability:

1. Cavities

2. Slag inclusions

3. Lack of fusion

4. Cluster porosity

5. Cracks

1. Deformation shrinkable crease

2. Deformation bulging, concave, down, pricked

3. Deformation buckled and twisted.

2. Slag inclusions

3. Lack of fusion

4. Cluster porosity

5. Cracks

C. Defects warping, shrinkable deformation:

There are three basic types:1. Deformation shrinkable crease

2. Deformation bulging, concave, down, pricked

3. Deformation buckled and twisted.

D. Other associated defects :

There are many other types of disabilities, but here we are interested in three basic types and the most common:

1. fit-up irregularities

2. parent material defects

3. incorrect welding technique

2. parent material defects

3. incorrect welding technique

II - The cause and corrective measures :

A. Defects visible to the eye:

1. cracks

All links of the metal weld and alloys are sensitive to cracking. Practical work showed that cracking (though very small) are the most dangerous Weld defects of the Weld link. Therefore if any defects appear compelled to fixes (grinding away, welded). The weld repair of details must be done according to the process for repairing high reliability.

Have 4 categories: hot cracking, cold cracking, thermal cracking, delamination and cracking of base metals after welding. Shown in 4 main types of cracking: Vertical cracks, cracked welds horizontal, vertical cracks base metal tearing, layering.

+ Prepare weld: before fitting weld connections are overlapping, closed weld size, thickness are not equal, not fitted with enhanced fixtures and not clean the grinding material .... Cause stress, before weld not provide heat sufficient minimum temperature.

+ Welding technique: between weld, weld layers wrong layout, no weld layout from the middle out, chase weld, weld segments. Welding current is too large to cause overheating in the heat affected zone around crack leading to local, long distance crack. Between the weld layer to the temperature is too high or too low, sometimes the wrong weld material or weld rods wrong.

- Remedies :

+ Prepare weld: Clean weld grinding before weld, avoid wind, rain, sun, dust ... right welding rod drying process, put the plug in the drying rods, thermal annealing ....

+ Welding technique: welding rod preparation, GTAW torch well and good implementation methods arc, arc weld with short column, maintaining a stable arc weld tanks, weld speeds and angles very well ...

To avoid causing porosity surface finish weld tanks happens slowly, proper technique, not abruptly interrupted arc will create air intake holes deep into the weld ...

Have 4 categories: hot cracking, cold cracking, thermal cracking, delamination and cracking of base metals after welding. Shown in 4 main types of cracking: Vertical cracks, cracked welds horizontal, vertical cracks base metal tearing, layering.

|

| Crack defects |

- Cause:

Usually occurs when welding alloy steel, high alloy, special alloys, HiStrenght, Duplex ... thick steel sheets> 20 mm.+ Prepare weld: before fitting weld connections are overlapping, closed weld size, thickness are not equal, not fitted with enhanced fixtures and not clean the grinding material .... Cause stress, before weld not provide heat sufficient minimum temperature.

+ Welding technique: between weld, weld layers wrong layout, no weld layout from the middle out, chase weld, weld segments. Welding current is too large to cause overheating in the heat affected zone around crack leading to local, long distance crack. Between the weld layer to the temperature is too high or too low, sometimes the wrong weld material or weld rods wrong.

|

| Crack defects |

|

| Crack defects |

|

| Crack defects |

2. Spatter, surface irregularities

Weld large and small, irregular, deflection sides, rugged, indented , overflap edge, metal spatter, arc strike, porosity create holes, slag inclusion ....

|

| Spatter surface defects |

|

| overlap defects |

- Cause:

+ Prepare weld: fitting irregular edge, incorrect angle, to weld small irregular, zigzag, rough surface materials, deflection fitting flanges,

+ Welding technique: weld surface unevenly due to uneven weld speed, wrong rod angle, observing poor weld tanks, welding current unstable, connecting rods incorrect, skilled workers are weak. ..

- Remedies :

+ Weld preparation: joints must be good, smooth edge, clean grinding, chamfered right angle, in accordance with the provisions welding processes. Welding current corresponding to welding rods and weld speed.

+ Welding technique: rod angle, angle to observe good weld pool, weld direction and weld correct posture, speed are weld, arc stability, moderate amplitude of shaking rods, screened well in the environment bad weather…

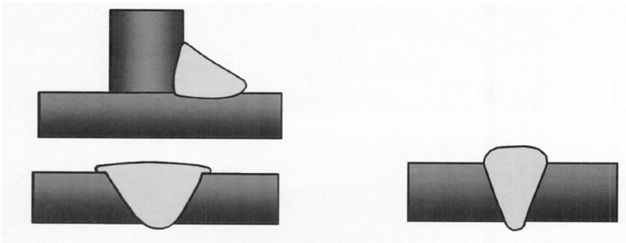

3. Contour Defects :

- Do not fill the weld, not fusion edge, undercut, slag inclusion, weld line poor profile, overlap. |

| lack of fusion , concave , excessive root defects |

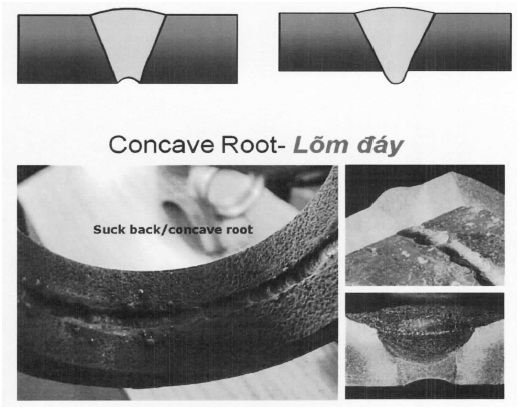

4. Root defects

- incomplet penatration root, lack of fusion root, concave root, excessive root penetration

|

| Incomplet penetration root defects |

|

| Concave root defects |

|

| Excessive root penetration defects |

- Cause:

+ Prepare bad welds: (root face too thick or too thin, root gap - the root gap is too narrow or too wide, beveled edge the original incorrectly ...) weld fitting edge deflection ...

+ weld current is too large or too small, voltage, select the incorrect .

+ Arc weld: wrong rod angle, unevenly speed, angle and direction arc observed incorrect arc column maintaining irregular oscillation method of welding rods wrong ...

+ Conditions: cramped position weld, difficult to observe, cover tightly wind, not enough air rushed inside (eg Argon, hli, nitrogen ...)

- Remedies :

+ Prepare weld: moderate to root face, corresponding to current and weld speed, root gap corresponding diameter welding rods, welding current and weld speed .... .Weld joints must be signed for approval QC accepted.

+ + Welding technique: use 2.6mm diameter rod or 3.2 (LB52U) electric weld - weld rods for tig 1.6-2.4 mm, rods and angles angle possible to observe the fusion of root liner. Tig Welding, choose the small porcelain cups easy to sway, speed oscillation arc and put the correct welding rod sufficiently fusion, lacking will be concave, convex or not much will be fusion up, constantly checking the concentration of fumigant and when oxygen in the tube welding white steel, duplex, alloy ...

5. Surface porosity

- Often create simple porosity, porosity cluster, or create holes deep vacuum arc that ends weld on a weld root or cap.

- Cause:

+ Prepare Weld: Weld Preparation is not good, dirty material, water, oil, grease, rust ... do not cover wind, rain, dust ... improper welding rod drying or drying temperature and over again, ruin class tig welding rods capsule ... rusted, dirty, sometimes mistakenly welding rod weld or soldering materials mistaken ...

+ Welding technique: Welding with electric current is too large, the arc column maintaining irregular let air to penetrate into an arc, arc weld techniques to break the drug less ... weld tig welding rods with low gas flow , dirty gas flow ,- Remedies :

+ Prepare weld: Clean weld grinding before weld, avoid wind, rain, sun, dust ... right welding rod drying process, put the plug in the drying rods, thermal annealing ....

+ Welding technique: welding rod preparation, GTAW torch well and good implementation methods arc, arc weld with short column, maintaining a stable arc weld tanks, weld speeds and angles very well ...

To avoid causing porosity surface finish weld tanks happens slowly, proper technique, not abruptly interrupted arc will create air intake holes deep into the weld ...

1 comments:

Excellent and very exciting site. Love to watch. Keep Rocking. best arc welders